Granules OE Strategy & Framework:

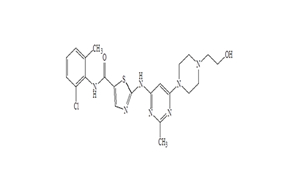

In line with our company’s vision, the need to be smart on all the three fronts (of Speed, Accuracy & Cost), together is also vital. Keeping this in view a structured “Operational Excellence” (OE) framework was designed & a detailed 5-years roadmap deploying OE program in the company was prepared in the year 2018 -as shown in Fig-1.

Fig-1: Operational Excellence Roadmap

OE Strategy Implementation: Successful implementation of OE initiative is always a top-down affair. So it started with a “Champions Program” for Granules Top Leadership team. A consulting company (LASSIB) was engaged to facilitate Champions program along with conducting Green Belt Training for the Plant & Function Heads. Further, company has deployed an elaborate program of OE capability building across levels. Fig-2 depicts- A four-tier courseware to train employees from Grass-root level to the Top Management.

Fig-1: Operational Excellence Roadmap

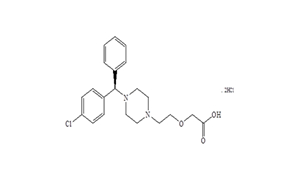

Fig-3: First Batch of Green Belt Program Fig-4: Granules team wins “CII Kai-Zen Competition”, 2020

Success Story: PFI Capacity Improvement Project- FY20-21

Average PFI Production Output for FY’20 was 1209 MT/Month and the market demand was much more. The objective of the project was to improve productivity using lean principles and tools without any significant additional capacity investment. The major causes that were hindering output were identified through brainstorming process. These were long changeover time, equipment breakdowns and approved material availability. To minimize changeover time, all the activities pertaining changeover were analysed on a time scale. Line clearance procedure was simplified & a specialised changeover crew was deployed to reduce changeover time. Equipment breakdown was analysed and preventive measures were taken to minimize downtime. Equipment utilisation was tracked everyday by AETs (Area Effectiveness Teams) in PFI. In addition, the ideas to further improve productivity were generated including lot size and spray rate increase.

This finally helped us to achieve average production output of 1614 MT/month in FY21, which resulted in an additional EBIDTA of INR 23 crores. This case study was recently presented in one of the CII competition and won accolades.

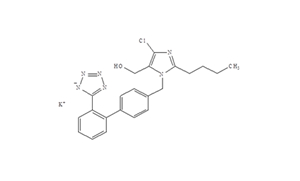

Outcome of the Initiative: One of the important outcomes of this initiative is “leadership development”. During the coaching sessions, managers are encouraged to undertake stretch goals. They also learnt influencing key stakeholder to garner their support & developed project management, communication and presentation skills. We believe this program will help us to become an agile & efficient Organisation.